EBM – Extrusion Blow Moulding

- Ability to produce bottles ranging in size from 1⁄2 oz up to 5L

- Tooling cavitation can range from a single unit cavity up to 8 cavities, depending on the size of the bottle.

Resins we use

- HDPE – High Density Polyethylene

- MDPE – Medium Density Polyethylene

- LDPE – Low Density Polyethylene

- PET-G – Copolyester

- PVC – Poly Vinyl Chloride

- PP – Polypropylene

- PCR – Post-Consumer Resin

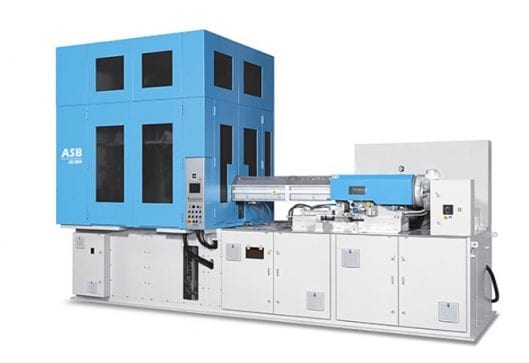

ISBM – Single Stage Injection Stretch Blow Moulding

- Ability to produce bottles ranging in size from 1⁄2 oz up to 10L

- Preform and bottle are produced all in one step

- Tooling cavitation can range from a single-unit cavity up to 12 cavities, depending on the size of the bottle.

Resins we use:

- PETE – Polyethylene Terephthalate

- PCR – Post-Consumer Resin

SBM – 2-Stage Stretch Blow Moulding

- Ability to produce bottles ranging in size from 1⁄2 oz up to 4L

- Ability to source and utilize preforms available in the market

- Tooling cavitation can range from a single-unit cavity up to 3 cavities, depending on the size of the bottle.

Resins we use:

- PETE – Polyethylene Terephthalate

- PCR – Post-Consumer Resin